Shima Seiki SDS-ONE A51-A52-A53-A54-A55 -A56-A60-A61-A62-A63-A64-A65

Planning and design are considered key elements in today's fashion industry. Specialized functions based on industry experience and know-how allow SDS-ONE to provide quick and powerful support of apparel design work for supporting continuously changing trends.

A full selection of brush types (airbrush, chalk, etc.), and a color palette of over 16 million colors are at your disposal.

The Draw program is used for creating fashion illustrations.

Color trend information can be organized into color palettes for creating color concepts.

Designs can be imported into spreadsheets for creating spec sheets.

A special colorway menu allows quick evaluation of various color combinations using realistic knit and weave textures. It also features a licensed Pantone color database for accurate color communication.

Various databases of useful patterns and structures are available. Patterns can be created easily by combining and editing these data.

Using the Automatic Pattern Repeat function, both normal and stepped repeats can be performed with controlled precision.

Textile software can be used to create various patterns such as check, dobby and double weave. A plentiful database of patterns is also available. Realistically woven images can be simulated as well.

An impressive variety of designs are available for any fashion application.

A collection of filters can be applied to images for deforming or creating interesting special effects.

Embroidery software features automatic punching, a pattern stitch database and special embroidery pen. Realistic simulations of embroideries can also be created.

SDS-ONE also functions as a full-featured apparel CAD system, with comprehensive patternmaking, grading and marking (PGM) functions for creating and fi ne-tuning patterns for all apparel applications. Patternmaking is especially important for quality shaping and WHOLEGARMENT knitting.

With SDS-ONE's patternmaking software, high-quality patterns can be created easily. Comprehensive drawing and editing functions allow detailed control approaching that of manual patternmaking.

Correct sizing of products can be achieved with grading software. Users can choose between pitch-formula and rule-formula grading. With such high-quality grading features as line-check and automatic pitch calculation, optimum grading pitch can be worked out for each product size.

In addition to manual marking, SDS-ONE's marking software features ultra-high speed automatic marking for instant creation of markers. The software is also capable of creating markers in sequence, allowing fully automated marking of multiple jobs overnight.

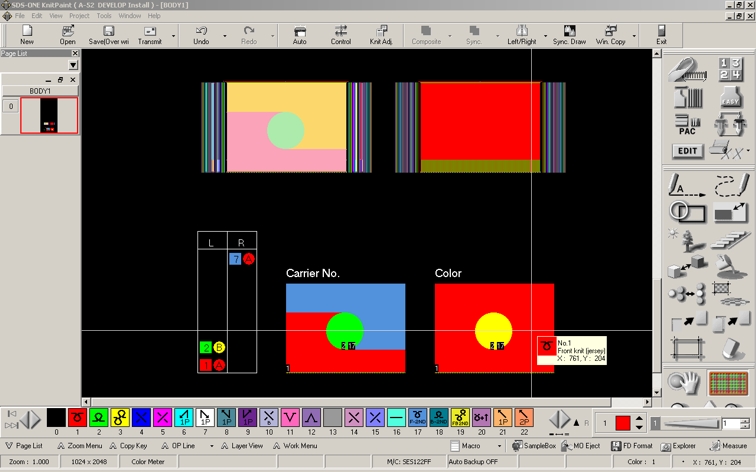

KnitCAD software features automatic programming based on conversion of patterns to number of loops. SDS-ONE also supports fashioning frequency input.

Structure patterns can be selected from an abundant database for visual confirmation on-screen. Knitting data is automatically created simultaneously.

SDS-ONE's Package database is a collection of Shima Seiki know-how that allows graphics-based programming. Its potential is maximized especially KnitCAD in 3D applications such as WHOLEGARMENT.

Basic knitting types and colors are set. Yarn carriers are automatically allocated as well.

Automatic Processing software creates machine data automatically.

Super Realistic loop simulation allows quick evaluation and presentation of virtual knitwear without sample-making. Since virtual sampling data is based on actual programming data, once approved, the design can go to production immediately.

From designing original yarns from scratch, to arranging existing yarns that are scanned-in and simulating the twisting of several yarns together, virtually spun yarns can be used in realistic loop simulation to create convincing fabric textures.

Loop simulation images are mapped onto photos of existing samples for a realistic representation of how the final product will look. These images can be used for presentations as well as for visual merchandising (VMD).

Data created on SDS-ONE is sent to various machinery for production. Shima Seiki's product lineup includes state-of-the-art computerized knitting machines and fabric cutting machines.

SDS-ONE's powerful graphics capability can be used for various promotional items at the retail level, such as point-of-purchase (POP) displays. Such items offer a very effective means for reaching the consumer with any special message you may have concerning a garment or collection.

High-resolution graphics support large-format printing of posters, as well as high-quality printing of buyer's catalogues and point-of-purchase displays.

SDS-ONE can be used for visual merchandising by simulating store displays.

Our SSS120 screen system works together with SDS-ONE to automatically photograph, cut-out and rotate mannequin samples to create animations for online shopping applications.

0 commentaires:

Enregistrer un commentaire

Remarque : Seul un membre de ce blog est autorisé à enregistrer un commentaire.