MET-5000 V2.0

In today's rapidly changing markets, flexibility and universality in turning pattern ideas into finished products is one of the most important challenges facing the modern knitting factory. Particular importance is attached to pattern preparation for electronically and mechanically controlled circular knitting machines. The Patronik 5000 pattern preparation system ideally addresses this need, in particular by ensuring convenient, easily mastered operation.

Processing of different file formats

Windows format: BMP, GIF, PCD, PCX, PNG, TIF

Terrot format: CK, MST, MTC, PIC, PM

Special formats: DAC, DAT, PCT WAC

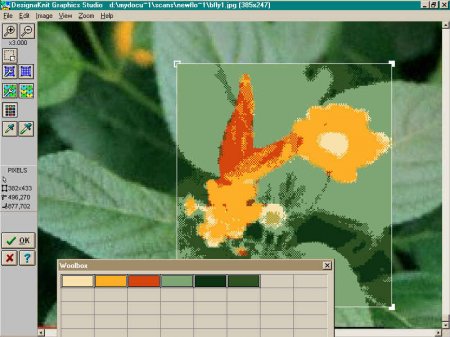

Automatic colour reduction for reworking scanned-in pictures

Easy-to-manage multiple colour workshop for patterns with up to 16 different colours for machines with stripers